Prancing horse goes electric

Ferrari has revealed the production-ready chassis and components of its first fully electric car, which marks a “milestone” in its multi-energy strategy of internal combustion, hybrid and plug-in powertrains.

The Elettrica combines technology with performance and driving pleasure while all of its main components have been developed and manufactured in-house.

This model will be the culmination of a long journey of technological research into electrification that began with the marque’s first hybrid solutions derived from its 2009 Formula 1 car.

From the 599 HY-KERS prototype of 2010 to the 2013 LaFerrari del 2013, and from the SF90 Stradale – the Maranello-based marque’s first plug-in hybrid – and the recent 296 GTB to the 849 Testarossa, Ferrari says it has consolidated the know-how needed to develop an electric car “capable of excelling in every dimension”.

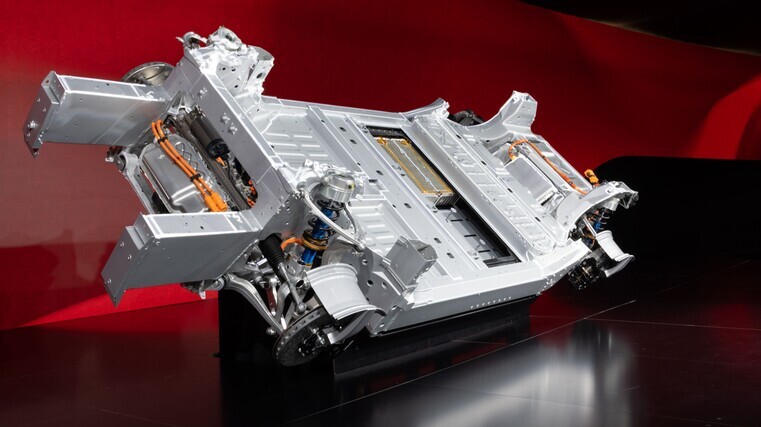

The Elettrica is now ready to go into production with more than 60 patented proprietary technological solutions. For the first time, both the chassis and bodyshell are manufactured with 75 per cent recycled aluminium, contributing to an overall saving of 6.7 tonnes of carbon dioxide for each unit built.

The architecture boasts short overhangs, an advanced driving position close to the front axle and a battery integrated into the floorplan. Modules are installed between the front and rear axles with 85 per cent concentrated in the lowest position possible to decrease the centre of gravity, which is 80mm lower than an equivalent ICE model.

At the rear, there is Ferrari’s first separate subframe in its history. It has been designed to reduce cabin noise and vibration while still ensuring stiffness and driving dynamics.

The third generation of the 48V active suspension system – originally introduced on the Purosangue and evolved for the F80 – boosts ride comfort, body control and dynamics by distributing cornering forces optimally over the four wheels.

The first all-electric Ferrari is equipped with two electric axles developed and built entirely in-house, each with a pair of synchronous permanent magnet engines and Halbach array rotors derived from F1.

The front axle has a power density of 3.23kW/kg and an efficiency of 93 per cent at peak power, while the rear axle attains a power density of 4.8kW/kg and the same peak efficiency. Capable of delivering up to 300kW, the front inverter is fully integrated into the axle and weighs just 9kg.

Designed and assembled in Maranello, the battery has an energy density of almost 195Wh/kg – the highest of any EV – and features a cooling system designed to optimise heat distribution and performance.

The three driving modes available – range, tour and performance – determine how energy, available power and traction are managed. The paddles behind the steering wheel let the driver access five progressively higher levels of torque and power delivery.

The dynamic parameters acquired by the vehicle control unit are updated 200 times per second to predictively manage suspension, traction and steering functions to ensure agility, stability and precision.

The car’s sound has been developed to accentuate the characteristics of the electric powertrain. A high-precision sensor picks up the mechanical vibrations of components, which are amplified to offer an “authentic” aural experience.

The unveiling of the new electric Ferrari will continue in early 2026 with a preview of interior design concepts. The world premiere will take place a few months later.